Laser Cutting

- Services

- Manufacturing

- Laser Cutting

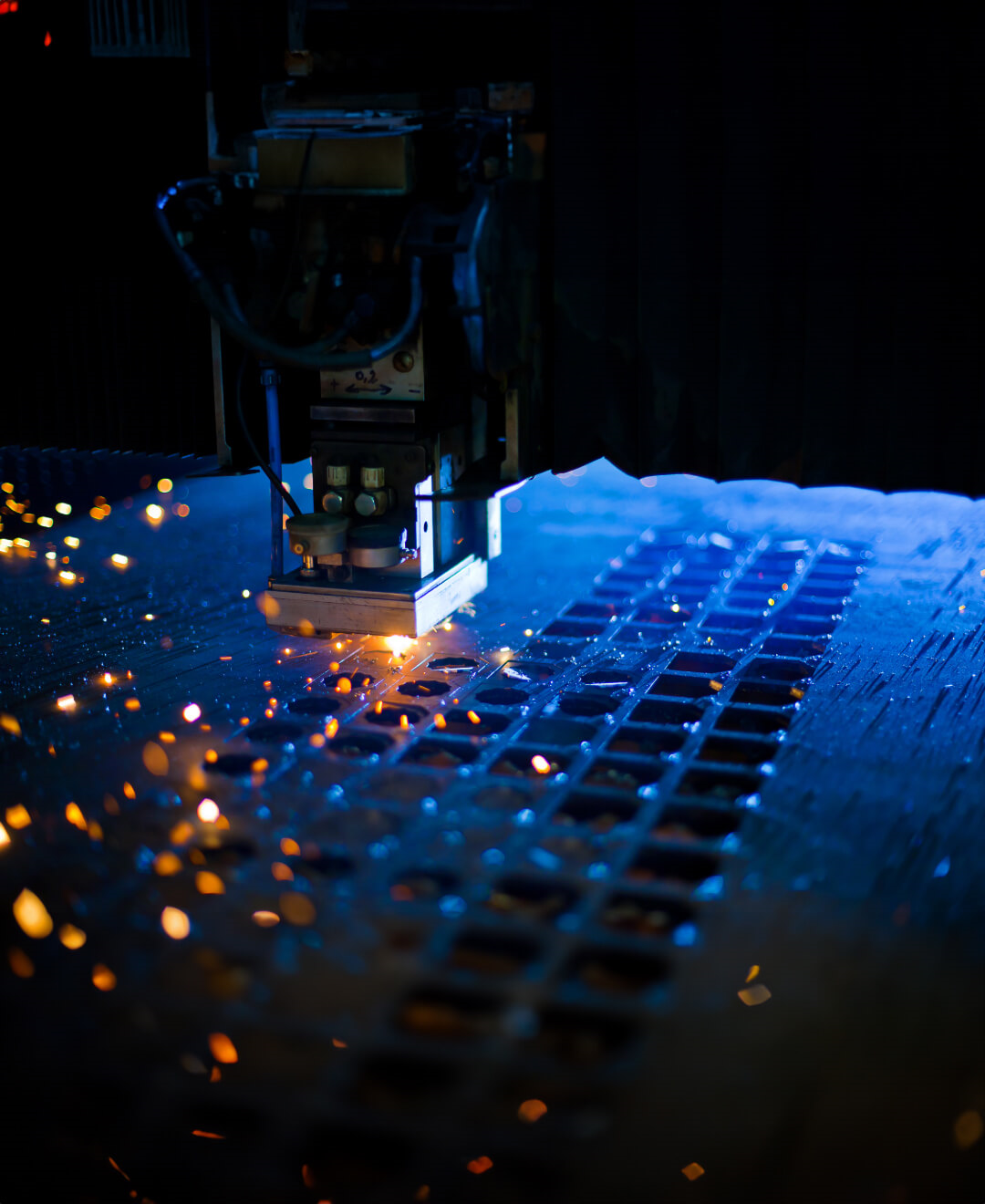

Metal Laser Cutting: A Precise and Efficient Metalworking Method

Metal laser cutting is an advanced manufacturing method used to cut and shape metals precisely. This technology utilizes the intensity of a laser beam to cut metal parts into the desired shapes.

Features of Metal Laser Cutting:

Precise Cutting: Laser technology has the ability to cut with sub-millimeter precision, making it ideal for cutting complex geometries and details.

Fast and Efficient: Laser cutting operates faster and more efficiently compared to other traditional cutting methods, accelerating production processes and reducing costs.

Flexibility: Metal laser cutting is suitable for different types and thicknesses of metals, offering a versatile solution for various industries and applications.

Applications of Metal Laser Cutting:

Automotive Industry: Commonly used in the production of automotive parts and custom designs.

Aerospace: Plays a significant role in producing precise and lightweight parts for the aerospace industry.

Machinery Manufacturing: Used for producing metal components and creating prototypes.

Medical Devices: Provides sterile and precise cutting for the production of medical devices.

Art and Decoration: Employed for cutting artistic designs and decorative metal products.

Advantages of Metal Laser Cutting:

Minimal Material Waste: Laser cutting minimizes material waste and increases efficiency.

Rapid Prototyping: Ideal for rapid prototyping, accelerating product development processes.

Cutting Quality: The cutting results are usually smooth and clean, enhancing the quality of the final products.

Metal laser cutting has become an indispensable part of modern industry. Its precision cutting capability, speed, and versatility benefit numerous industries and applications. By utilizing this technology, you can make the design and production processes of metal products more effective and gain a competitive advantage. Metal laser cutting is a revolutionary technology in the field of metalworking and will continue to provide further innovation and development in the future.